Mastering BOP Well Control Hose: Key Features and Benefits for Enhanced Safety and Efficiency

Jul 20,2025

Mastering BOP Well Control Hose: Key Features and Benefits

Table of Contents

- 1. Introduction to BOP Well Control Hose

- 2. What is BOP Hose?

- 3. Key Features of BOP Well Control Hose

- 3.1 Material Composition

- 3.2 Pressure Rating

- 3.3 Temperature Resistance

- 3.4 Flexibility and Maneuverability

- 4. Benefits of Using BOP Well Control Hose

- 5. Applications of BOP Well Control Hose

- 6. Maintenance and Inspection of BOP Hoses

- 7. Common Issues and Solutions

- 8. Conclusion

- 9. Frequently Asked Questions

1. Introduction to BOP Well Control Hose

In the realm of drilling operations, the **Blowout Preventer (BOP)** well control hose plays a pivotal role in ensuring safety and efficiency. As drilling processes become increasingly complex, the demand for reliable equipment intensifies. The BOP hose is designed to manage high pressures and prevent blowouts during drilling. This article delves into the core features and benefits of BOP well control hoses, providing an invaluable resource for industry professionals.

2. What is BOP Hose?

A **BOP well control hose** is a critical component in the drilling industry, particularly in **oil and gas extraction**. It is specifically engineered to connect the blowout preventer to various hydraulic systems, facilitating the control of pressure in the well. These hoses are vital for maintaining well integrity and preventing catastrophic failures. Understanding its construction and operational characteristics is essential for those involved in drilling operations.

3. Key Features of BOP Well Control Hose

To make an informed decision regarding the selection of BOP hoses, it’s essential to consider their key features.

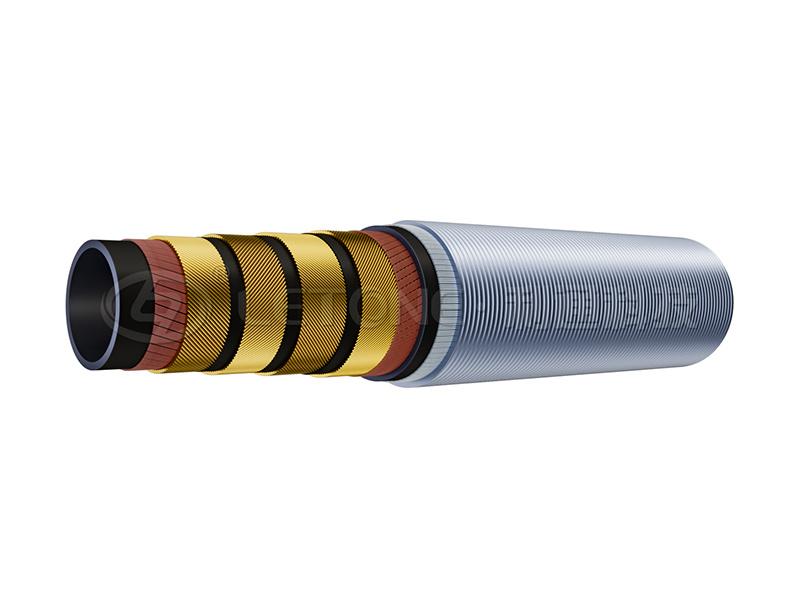

3.1 Material Composition

The material composition of BOP hoses is crucial for their performance. Typically made from **synthetic rubber** and reinforced with **steel wire**, these hoses are designed to withstand extreme conditions. The materials used ensure high resistance to wear and tear, allowing for prolonged use in challenging environments.

3.2 Pressure Rating

BOP hoses are rated for high-pressure applications, often exceeding **10,000 PSI**. This pressure rating is fundamental for ensuring that the hose can handle the extreme pressures encountered during drilling. A reliable pressure rating also enhances safety by preventing hose failures during critical operations.

3.3 Temperature Resistance

BOP hoses are designed to function effectively across a broad temperature range. They can endure high temperatures generated by drilling operations without compromising integrity. This thermal stability is essential for maintaining performance in dynamic drilling conditions.

3.4 Flexibility and Maneuverability

Flexibility is another defining feature of BOP well control hoses. Their design allows for easy maneuvering in tight spaces, which is often a requirement in drilling operations. This flexibility not only aids in the installation process but also ensures that hoses can adapt to various operational configurations.

4. Benefits of Using BOP Well Control Hose

Employing BOP hoses in drilling operations yields several significant benefits that contribute to overall operational success.

4.1 Enhancing Safety

Safety is paramount in the drilling industry, and BOP hoses play a crucial role in enhancing it. By effectively managing pressure and preventing blowouts, these hoses protect both personnel and equipment. The use of quality BOP hoses minimizes the risk of accidents and instills confidence in operational safety.

4.2 Improving Operational Efficiency

BOP well control hoses contribute to operational efficiency by enabling quicker response times during emergencies. Their reliability reduces downtime, allowing drilling crews to focus on productivity. Moreover, the flexibility of these hoses simplifies the setup and adjustment processes, further streamlining operations.

4.3 Cost-Effectiveness

Investing in high-quality BOP hoses can lead to significant savings in the long run. Their durability and resilience reduce the need for frequent replacements, lowering maintenance costs. Additionally, enhanced safety and efficiency translate into fewer operational disruptions, which is financially beneficial.

5. Applications of BOP Well Control Hose

BOP hoses find their applications primarily in the **oil and gas industry**, but their versatility extends to other sectors as well. They are used in various drilling environments, including offshore platforms and onshore wells. Understanding the specific applications helps in choosing the right hose for the task.

6. Maintenance and Inspection of BOP Hoses

Regular maintenance and inspection of BOP hoses are essential to ensure their longevity and reliability. Operators should conduct routine checks for wear, leaks, and damage. Proper storage and handling practices further enhance the lifespan of these critical components.

7. Common Issues and Solutions

Despite their robustness, BOP hoses may encounter issues such as abrasion, kinking, or pressure fluctuations. Identifying these problems early can prevent catastrophic failures. Solutions include timely replacements, using protective coverings, and adjusting operational procedures to minimize stress on the hoses.

8. Conclusion

Mastering the use of BOP well control hoses is essential for ensuring the safety and efficiency of drilling operations. Understanding their features, benefits, and maintenance requirements equips professionals in the construction and decorative materials industry with the knowledge necessary for informed decision-making. By investing in high-quality BOP hoses, companies can enhance operational performance while prioritizing safety.

9. Frequently Asked Questions

What is the typical lifespan of a BOP well control hose?

The lifespan of a BOP well control hose can vary based on usage and maintenance but typically ranges from 5 to 10 years with proper care.

How often should BOP hoses be inspected?

BOP hoses should be inspected regularly, ideally before each drilling operation, and at least annually for comprehensive assessments.

Can BOP hoses be repaired?

While minor damages can be repaired, it is often safer and more cost-effective to replace excessively worn or damaged hoses.

What should I look for when purchasing BOP hoses?

When purchasing BOP hoses, consider factors such as pressure rating, temperature resistance, flexibility, and material composition to ensure they meet your operational needs.

Are there regulatory standards for BOP hoses?

Yes, BOP hoses must meet various industry standards and regulations, including those established by organizations such as the American Petroleum Institute (API) to ensure safety and performance.

This detailed exploration of BOP well control hoses highlights their significance in the drilling industry. By focusing on their features, benefits, and maintenance practices, professionals can ensure efficient and safe operations.

PREVIOUS:

Contact Us

E-mail :

admin@lionflex.cn

Mobile:

+86-15921166698

Address:

Hangzhou Xiaoshan District Heshang Town Daqiao Industrial Zone