Understanding BOP Well Control Hoses: Essential Components for Safe Drilling Operations

Nov 29,2025

BOP (Blowout Preventer) well control hoses are critical components in the drilling industry, primarily designed to manage well pressure and control fluid flow during drilling operations. These hoses serve as the connective link between the blowout preventer and other equipment, ensuring that the system operates smoothly and safely. The functionality of these hoses is paramount, as they are responsible for containing high-pressure fluids and preventing blowouts, which can result in catastrophic incidents.

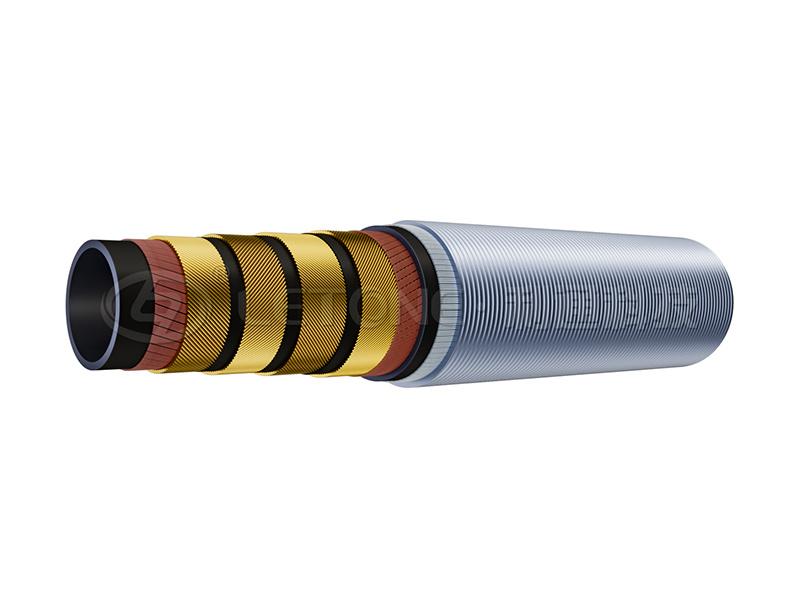

One of the primary materials used in BOP well control hoses is synthetic rubber, which offers excellent resistance to high pressures and temperatures. This characteristic is essential because the hoses must withstand extreme conditions typical in drilling operations. Additionally, these hoses are reinforced with steel wire braiding or spiral construction, which enhances their durability and flexibility, allowing for easier handling and installation.

The importance of BOP well control hoses extends beyond just their physical properties. They play a crucial role in the overall safety and efficiency of drilling operations. In the event of unexpected pressure surges, the blowout preventer relies on these hoses to maintain control over the well, thereby preventing blowouts that could lead to loss of life, environmental disasters, and significant financial losses.

Proper maintenance of BOP well control hoses is vital to ensure their longevity and functionality. Regular inspections should be conducted to check for wear, tear, or any signs of damage. Ensuring that these hoses are free from kinks, excessive bending, or exposure to harsh chemicals can significantly extend their operational life. Additionally, following the manufacturer's guidelines for storage and handling is crucial to avoid any degradation of the hose material.

In summary, BOP well control hoses are indispensable in the drilling industry, providing essential support to blowout preventers and ensuring safe drilling practices. Their construction, maintenance, and functionality are critical to preventing blowouts and protecting both personnel and the environment. Understanding these aspects can greatly contribute to a professional's ability to implement effective safety measures and enhance operational efficiency in drilling projects.

One of the primary materials used in BOP well control hoses is synthetic rubber, which offers excellent resistance to high pressures and temperatures. This characteristic is essential because the hoses must withstand extreme conditions typical in drilling operations. Additionally, these hoses are reinforced with steel wire braiding or spiral construction, which enhances their durability and flexibility, allowing for easier handling and installation.

The importance of BOP well control hoses extends beyond just their physical properties. They play a crucial role in the overall safety and efficiency of drilling operations. In the event of unexpected pressure surges, the blowout preventer relies on these hoses to maintain control over the well, thereby preventing blowouts that could lead to loss of life, environmental disasters, and significant financial losses.

Proper maintenance of BOP well control hoses is vital to ensure their longevity and functionality. Regular inspections should be conducted to check for wear, tear, or any signs of damage. Ensuring that these hoses are free from kinks, excessive bending, or exposure to harsh chemicals can significantly extend their operational life. Additionally, following the manufacturer's guidelines for storage and handling is crucial to avoid any degradation of the hose material.

In summary, BOP well control hoses are indispensable in the drilling industry, providing essential support to blowout preventers and ensuring safe drilling practices. Their construction, maintenance, and functionality are critical to preventing blowouts and protecting both personnel and the environment. Understanding these aspects can greatly contribute to a professional's ability to implement effective safety measures and enhance operational efficiency in drilling projects.

Contact Us

E-mail :

admin@lionflex.cn

Mobile:

+86-15921166698

Address:

Hangzhou Xiaoshan District Heshang Town Daqiao Industrial Zone