What Every Builder Should Know About Furnace Coolant Hoses

Dec 04,2025

What Every Builder Should Know About Furnace Coolant Hoses

Understanding Furnace Coolant Hoses

Furnace coolant hoses play a critical role in the heating systems of residential and commercial structures. They are designed to transport coolant to and from the furnace, ensuring efficient heating and preventing overheating. Understanding their function is vital for builders and contractors who aim to provide quality work.

The Importance of Furnace Coolant Hoses

In any heating system, the efficiency and safety of the furnace depend significantly on the performance of the coolant hoses. They help maintain the optimal temperature of the furnace, thus ensuring that the heating system operates effectively. Failure to understand the importance of these hoses can lead to serious issues, including system malfunctions and dangerous overheating.

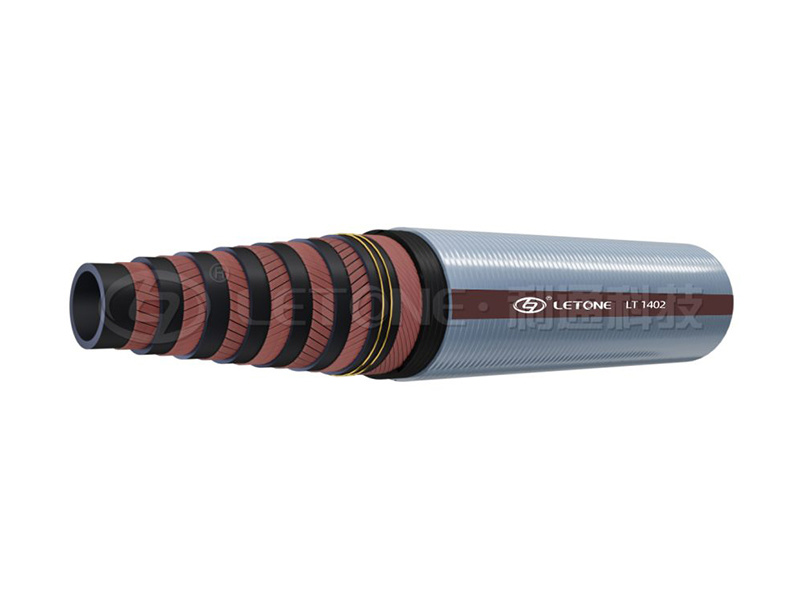

Types of Furnace Coolant Hoses

Choosing the right type of furnace coolant hose is crucial. Here are the most common types:

1. Rubber Hoses

Rubber hoses are widely used due to their flexibility and resistance to temperature changes. They are excellent for standard heating systems but may degrade over time when exposed to certain chemicals.

2. Silicone Hoses

Silicone coolant hoses are often preferred for high-temperature applications. They offer superior thermal stability and can last longer than rubber hoses, making them ideal for modern heating systems.

3. Stainless Steel Hoses

Stainless steel hoses are durable and resistant to corrosion. They are often used in industrial settings where extreme conditions are present, providing long-lasting performance.

Key Factors to Consider When Selecting Furnace Coolant Hoses

When choosing coolant hoses for a furnace system, several factors should be taken into account:

1. Temperature Resistance

Different hoses have varying temperature ratings. It's essential to select hoses that can withstand the operational temperatures of the furnace to prevent premature failure.

2. Chemical Compatibility

Ensure that the materials of the hose can resist the types of coolant used in the system. Incompatible materials can lead to degradation and leaks.

3. Size and Fit

Hoses must fit correctly to prevent leaks and ensure efficient coolant flow. Builder specifications should be followed precisely when determining hose sizes.

4. Flexibility

Consider the layout of the system. Flexible hoses can make installation easier, especially in tight spaces or complex configurations.

Installation of Furnace Coolant Hoses

Proper installation of furnace coolant hoses is critical to ensuring the heating system functions efficiently. Here are some essential tips for builders:

1. Preparation

Before installation, inspect the furnace and surrounding areas for any signs of damage. Ensure that all components are clean and free from debris.

2. Cutting and Fitting

When cutting hoses, use a sharp blade to make a clean cut. Ensure that the ends are trimmed evenly to allow for a proper fit with connectors.

3. Securing Hoses

Use high-quality clamps to secure hoses to their fittings. This prevents leaks and ensures that coolant flows effectively throughout the system.

4. Testing for Leaks

After installation, conduct a thorough inspection for leaks. Run the furnace and monitor for any signs of coolant escaping from the hoses.

Maintenance Tips for Furnace Coolant Hoses

Regular maintenance can significantly extend the lifespan of furnace coolant hoses. Here are some best practices:

1. Routine Inspections

Schedule regular inspections to check for wear and tear. Look for cracks, bulges, or signs of leaking coolant.

2. Clean Hoses

Keep hoses clean to prevent blockages. This can be achieved by wiping them down with a damp cloth and ensuring that they are free from debris.

3. Replace When Necessary

If any signs of damage are detected during inspections, replace the hoses immediately. Delaying replacement can lead to significant issues down the line.

4. Monitor Coolant Levels

Regularly check coolant levels in the system. Low levels can cause overheating and may indicate leaks in the hoses.

Troubleshooting Common Issues with Furnace Coolant Hoses

Despite best efforts, issues may arise with furnace coolant hoses. Being able to troubleshoot common problems can save time and money.

1. Identifying Leaks

If you suspect a leak, inspect the hoses visually and use a coolant dye to help locate the source. Leaks often occur at connection points or areas of wear.

2. Overheating Symptoms

If the furnace is overheating, check the hoses for blockages or kinks, which can restrict coolant flow. Also examine the coolant levels to ensure they are adequate.

3. Unusual Noises

Hoses that are making strange noises may be experiencing vibration issues. Ensure they are properly secured and not rubbing against other components.

4. Discoloration or Damage

Discoloration in hoses can be a sign of chemical degradation. Regularly check hoses for any signs of damage, and replace them as needed.

Frequently Asked Questions (FAQs)

1. How often should furnace coolant hoses be replaced?

Furnace coolant hoses should be inspected at least once a year and replaced every 5-7 years, depending on the material and condition.

2. Can I use regular rubber hoses for my furnace?

It depends on the furnace specifications. While rubber hoses are commonly used, ensure they are compatible with the coolant and temperature requirements.

3. What are the signs of a failing coolant hose?

Signs include visible cracks, bulges, leaks, or the presence of coolant around hose connections.

4. How can I prevent coolant hose damage?

Regular inspections, proper installation, and monitoring of coolant levels can help prevent damage to coolant hoses.

5. Is it necessary to hire a professional for installation?

While experienced builders can install hoses, hiring a professional ensures proper installation and reduces the risk of future issues.

Conclusion

Understanding furnace coolant hoses is essential for builders who strive for quality in their construction projects. By selecting the right type of hose, ensuring proper installation, and maintaining them diligently, builders can enhance the reliability of heating systems while ensuring safety. With the knowledge gained from this comprehensive guide, you can make informed decisions that will lead to successful installations and satisfied clients. Being proactive in troubleshooting and maintenance will only solidify your reputation as a skilled professional in the building and construction industry.

Contact Us

E-mail :

admin@lionflex.cn

Mobile:

+86-15921166698

Address:

Hangzhou Xiaoshan District Heshang Town Daqiao Industrial Zone